R&D – Production

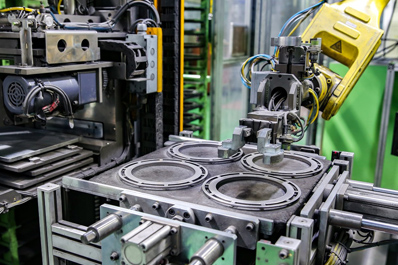

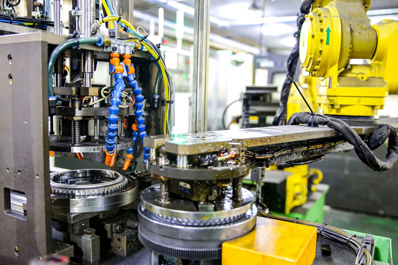

As automotive industry evolve, the demands for powder metallurgy products have increased significantly and its strengths have been proven through multiple applications. PM parts are lighter, highly heat resistant, and durable while it can maintain all properties requested and required by clients. In addition, PM parts are manufactured ‘nearly net shape’, which then requires minimal post processes. In order to leverage the edge, GLOSCO makes consistent efforts in developing wider range of PM applications while achieving lighter weight and cost effective solutions.

Proprietary Technology

GLOSCO uses proprietary technology in designing oil pump rotor tooth. With this technology, GLOSCO manufactures parts of irreplaceable quality.

> Patented Geroter tooth profile design method using super ellipse(Oil Pumps)

> Increased volumetric efficiency, improved flow pulsation and durability(wear resistance), minimized noise and vibration

> Patented Geroter tooth profile design method using super ellipse(Oil Pumps)

> Increased volumetric efficiency, improved flow pulsation and durability(wear resistance), minimized noise and vibration

KEY Technology and Applications

> Multi-layer brazing for the mass production of F150 Gear shift lever

> GLOSCO’s provision of machining optimization process technology contributed to a governmental research studies in cost minimization of mass producing Rotors for VCT

> Carrier(Transfer Case) development using sinter brazing technology

> High-density tooth compaction method to improve impulse precision of Tone Wheels

> Double Pressing Double Sintering(DPDS) technology to meet high density requirements

> Sinter hardening method to eliminate excess heat treatment processes

> GLOSCO’s provision of machining optimization process technology contributed to a governmental research studies in cost minimization of mass producing Rotors for VCT

> Carrier(Transfer Case) development using sinter brazing technology

> High-density tooth compaction method to improve impulse precision of Tone Wheels

> Double Pressing Double Sintering(DPDS) technology to meet high density requirements

> Sinter hardening method to eliminate excess heat treatment processes

R&D – Quality Control

“Quality, it is our only answer.”

- ChongWhal Rhee, founder of GLOSCO

ChongWhal Rhee, founder of GLOSCO, carried forward a single philosophy that defined his leadership.

“It is innovation that drives a company forward, but the obsession for quality is the fuel that needs to be in place”. GLOSCO has been instilled with this unique mindset that still navigates the company to this date. When problems arise, GLOSCO tackles it head on, bring the problem into the light, and dissect it and deal with it in the most straight forward and transparent ways. GLOSCO does not only solve the problems, but extends to take the lessons learned into future innovations.

“It is innovation that drives a company forward, but the obsession for quality is the fuel that needs to be in place”. GLOSCO has been instilled with this unique mindset that still navigates the company to this date. When problems arise, GLOSCO tackles it head on, bring the problem into the light, and dissect it and deal with it in the most straight forward and transparent ways. GLOSCO does not only solve the problems, but extends to take the lessons learned into future innovations.

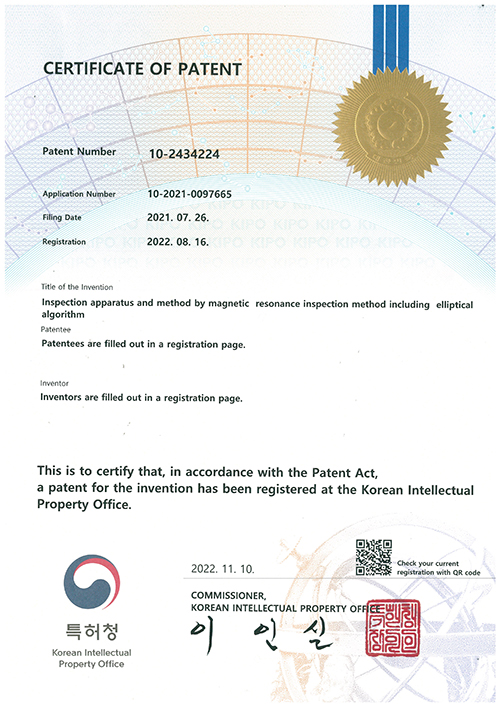

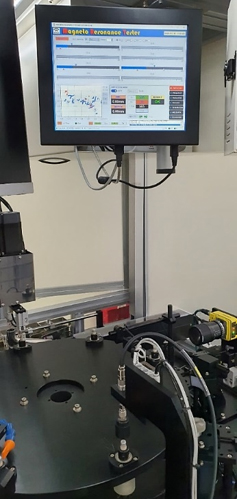

MRT

Magnetic Resonance Tester

MRT uses magnetic field’s resonating property with the electromagnetic wave to detect physical anomalies.

The device reads and records the resonance frequency of the subjected parts and detects any parts resonating differently from a normal pattern. This method is incredibly accurate and fast, it allows GLOSCO to run physical quality testing on all parts within the mass production processes.

Strength:

1) Optimized for 100% NDT physical defect detection

2) Each part is assessed within 0.2-0.5 seconds.

3) High detectability for micro cracks, scratch, burr, and weight imbalance for both internal and surficial of all parts

4) Applicable for highly complex parts

5) Collection and store of all data, and pattern development capability for advanced analysis.

6) High accuracy as the device uses 8 different frequencies to compare different physical attributes

2) Each part is assessed within 0.2-0.5 seconds.

3) High detectability for micro cracks, scratch, burr, and weight imbalance for both internal and surficial of all parts

4) Applicable for highly complex parts

5) Collection and store of all data, and pattern development capability for advanced analysis.

6) High accuracy as the device uses 8 different frequencies to compare different physical attributes

Application of this technology in mass production environment is a proud result of GLOSCO’s partnership with RAYNAR, a magnetic resonance device specialist.

This technology has completed a joint patent registration as the microcrack inspection equipment for sintered products.

( Patent registration number : 10-2434224 )

This technology has completed a joint patent registration as the microcrack inspection equipment for sintered products.

( Patent registration number : 10-2434224 )