> In North America, GLOSCO currently supplies over 3 million parts to customers on annual average.

> GLOSCO’s powder metallurgy parts have been applied to over 50 types of vehicles globally.

OEM Key Statistics

GLOSCO’s Cumulative Automotive OEM Supply Statistics at a Glance

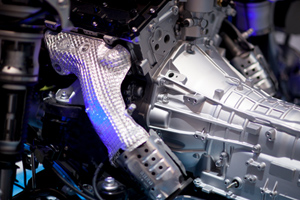

Automatic Transmission Parts(6 Speed, 8 speed, 10 speed) for over 10 Million vehicles

Engine parts for over 30 Million vehicles

Seatbelt Parts over 12.5 Million vehicles

CV Joints for over 15 Million vehicles

Steering Parts for over 6.5 Million commercial vehicles

Capability

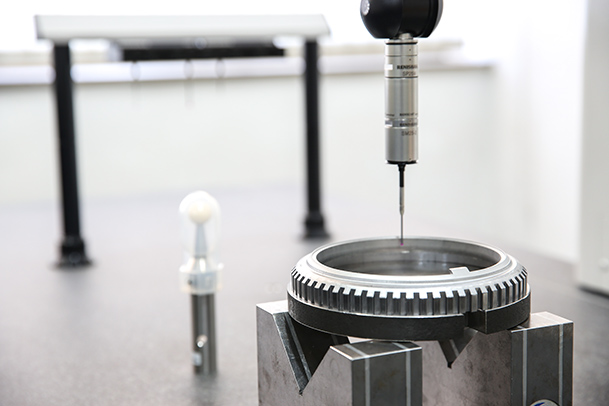

Quality Control

Dedicated Overseas Business and Quality Support Team100% On Time Delivery Since 2006

Systematic Quality Control & Periodic Customer Visits

Patented Quality Control Capability(MRT)

Capability

Up to 850T Compcating PressesUp to 800T Sizing Presses

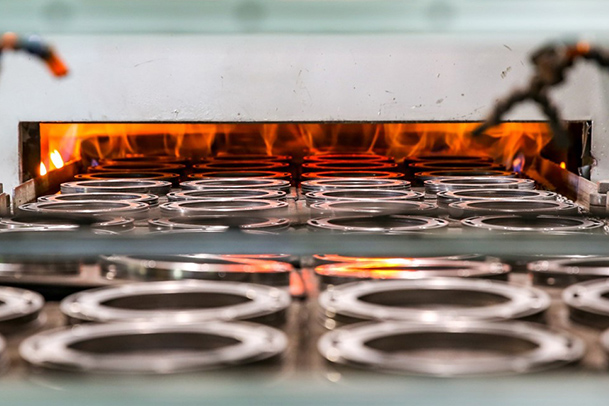

36” Furnaces

In-House Blending of Powder Metal

In-House Machining

In-House Tooling

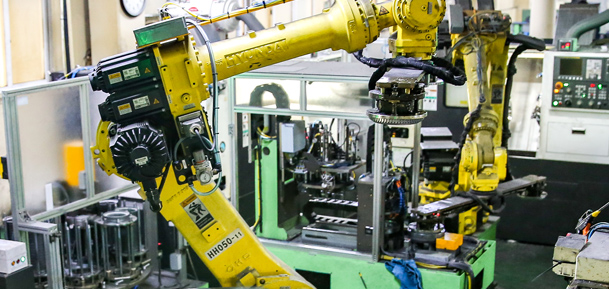

Line Automation

Financial Stability

Strong and Healthy Financial Status100% Owned Private Company

Continuing Growth and Capital Investment

Low Debt to Capital Management Policy

Global Presence

Global Warehouses in Mississauga, Canada and Wytheville, USVMI Available DDP Available

Local Agents in US & CANADA

Prompt Response, No Language Barrier

Applications

Transmission / Engine / Oil Pump / Safety / Steering / Automotive Electric / ABS Brake

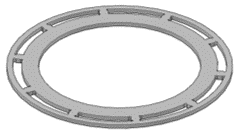

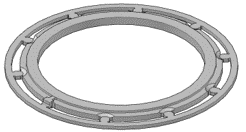

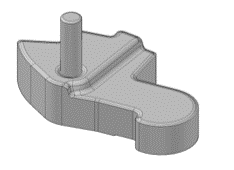

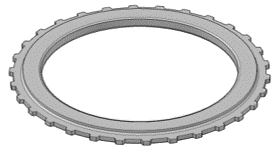

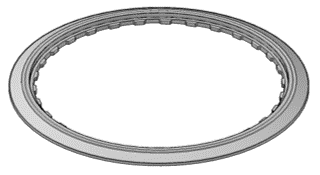

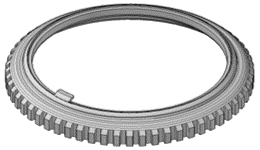

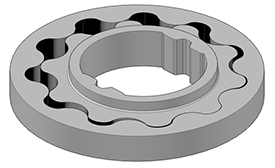

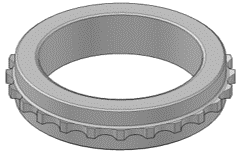

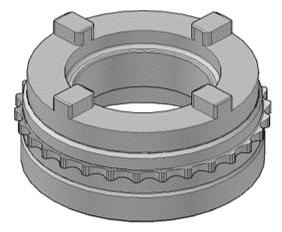

Transmission Plates, Transmission Tonewheel, Transmission Hub, Chain Sprocket, Camshaft Ring, Water Pump Pulley, EGR Valve, ABS Ring, Cam Ring, Seatbelt Pawl, Gears, Gerotor, Rotor, Oil Pump Rotor, Pump Rotor, EHA Rotor, PTO Pump, Balance shaft Module, Electro Hydraulic Actuator, Electric Oil Pump, Electric Vacuum Pump, and more.

Equipment

Having 40+ compacting press machines ranging from 20T to 850T, sizing press machines Up to

800T, 10+ sintering furnaces, and 10+ CNC machines, GLOSCO is well equipped to handle high volume demands for all types and size ranges of ferrous Powder Metallurgic(P/M) parts.

In order to maximize quality control capabilities and minimize cost factors, most P/M productions and processes required are done in-house. In-house capability in blending of raw materials, Tool building, Compaction & Sintering, and CNC machining greatly contributes to precise quality control resulting in superior quality of production. GLOSCO is your one stop partner for all things power metal, and takes pride in the products that leave the facilities and fully stands behind its products.